- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Advertising Cutting Machine | Digital Cutter

DESCRIPTION

The advertising cutting machine’s integrated cutting system is a remarkable innovation. By combining the three key advantages of performance, speed, and quality, it offers a powerful solution for the advertising industry.

The cooperation with modular tools allows it to meet the customized needs of users. This flexibility enables the machine to adapt to a wide range of advertising production requirements. Whether it’s full cutting, half cutting, milling, punching, creating creases, or marking, the system can quickly complete various processes. Having all these functions on one machine is a significant advantage as it saves space and streamlines the production workflow.

This machine empowers users to process novel, unique, and high-quality advertising products more quickly and accurately within a limited time and space. By doing so, it effectively improves the industry competitiveness of advertising production users. It helps them stand out in the market by creating exceptional advertising products that attract attention and convey brand messages effectively. Ultimately, it assists users in achieving excellent brand recognition and success.

Video

Advantages

1. Advertising cutting machine can process various signage solutions, such as signs for facades or shop windows, large and small car wrap signs, flags and banners, roller blinds or folding walls – textile advertising, Advertising cutting machine provides you with personalized concepts for high-quality and efficient cutting of textile advertising materials.

2. Advertising cutting machine can provide you with customized solutions for your requirements through innovative software tools and modern digital cutting technology.

3. Whether it is half-through cutting or cutting according to the final model, Advertising cutting machine can meet the highest requirements of precision, quality and production efficiency.

Equipment parameters

| Model | BO-1625 (Optional) |

| Maximum cutting size | 2500mm×1600mm (Customizable) |

| Overall size | 3571mm×2504mm×1325mm |

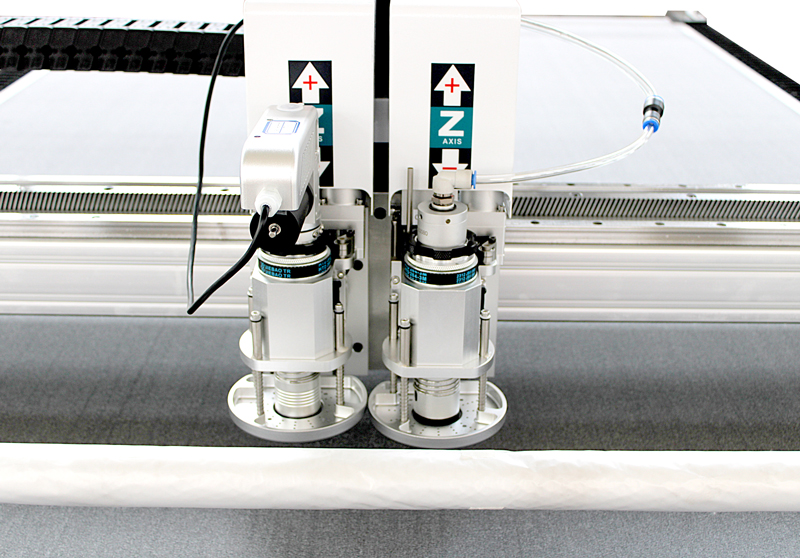

| Multi-function machine head | Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions (Optional) |

| Tool configuration | Electric vibration cutting tool, flying knife tool, milling tool, drag knife tool, slotting tool, etc. |

| Safety device | Infrared sensing, sensitive response, safe and reliable |

| Maximum cutting speed | 1500mm/s (depending on different cutting materials) |

| Maximum cutting thickness | 60mm (customizable according to different cutting materials) |

| Repeat accuracy | ±0.05mm |

| Cutting materials | Carbon fiber/prepreg, TPU/base film, carbon fiber cured board, glass fiber prepreg/dry cloth, epoxy resin board, polyester fiber sound-absorbing board, PE film/adhesive film, film/net cloth, glass fiber/XPE, graphite/asbestos/rubber, etc. |

| Material fixing method | vacuum adsorption |

| Servo resolution | ±0.01mm |

| Transmission method | Ethernet port |

| Transmission system | Advanced servo system, imported linear guides, synchronous belts, lead screws |

| X, Y axis motor and driver | X axis 400w, Y axis 400w/400w |

| Z, W axis motor driver | Z axis 100w, W axis 100w |

| Rated power | 11kW |

| Rated voltage | 380V±10% 50Hz/60Hz |

Components of Composite material cutting machine

Multi-function machine head

Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions. The diversified machine head configuration can freely combine standard machine heads according to different processing requirements, and can flexibly respond to various production and processing requirements. (Optional)

Components of Composite material cutting machine

All-round safety protection

Emergency stop devices and safety infrared sensors are installed at all four corners to ensure maximum operator safety during high-speed movement of the machine.

Components of Composite material cutting machine

Intelligence brings high performance

High-performance cutter controllers are equipped with high-performance servo motors, intelligent, detail-optimized cutting technology and precise, maintenance-free drives. With excellent cutting performance, low operating costs and easy integration into production processes.

Sample of Advertising Cutting Machine

Energy consumption comparison

- Cutting Speed

- Cutting Accuracy

- Material Utilization Rate

- Cutting Cost

4-6 times + Compared with manual cutting, work efficiency is improved

Bolay machine speed

Manual cutting

High precision, high efficiency, and improved material utilization

Boaly Machine cutting accuracy

Manual cutting accuracy

Automatic typesetting system saves more than 20% of materials compared with manual typesetting

Bolay machine cutting efficiency

Manual cutting efficiency

Bolay machine cutting cost

Manual cutting cost

Product Introduction

-

Electric vibrating knife

-

Round knife

-

Pneumatic knife

Electric vibrating knife

Equipped with a wide variety of blades, it is suitable for processing different materials such as paper, cloth, leather and flexible composite materials.

– Fast cutting speed, smooth edges and cutting edges

Round knife

– Mainly used in clothing fabrics, suits, knitwear, underwear, wool coats, etc.

– Fast cutting speed, smooth edges and cutting edges

Pneumatic knife

– For materials that are soft, stretchable, and have high resistance, you can refer to them for multi-layer cutting.

– The amplitude can reach 8mm, and the cutting blade is driven by the air source to vibrate up and down.

Worry free service

-

Three year warranty

-

Free installation

-

Free training

-

Free maintenance

OUR SERVICES

-

01 /

Which materials can we cut?

The advertising cutting machine can process various signage schemes, including storefront or shop window signs, car packaging signs, soft signs, display racks, and labels and stickers of different sizes and models.

-

02 /

What is the maximum cutting thickness?

The cutting thickness of the machine depends on the actual material. If cutting multi-layer fabric, it is suggested to be within 20 – 30mm. If cutting foam, it is suggested to be within 100mm. Please send me your material and thickness so that I can further check and give advice.

-

03 /

What is the machine cutting speed?

The machine cutting speed is 0 – 1500mm/s. The cutting speed depends on your actual material, thickness, and cutting pattern, etc.

-

04 /

What is the machine warranty?

The machine has a 3-year warranty (not including consumable parts and human damage).

-

05 /

How long is the service life of an advertising cutting machine?

The service life of an advertising cutting machine is generally around 8 to 15 years, but it will vary depending on a variety of factors.

The following are some factors that affect the service life of an advertising cutting machine:

- **Equipment quality and brand**: Advertising cutting machines with good quality and high brand awareness use high-quality components and advanced manufacturing processes, and have a relatively long service life.

- **Use environment**: If the advertising cutting machine is used in a harsh environment, such as high temperature, humidity, dust, etc., it may accelerate the aging and damage of the equipment and shorten its service life. Therefore, it is necessary to provide the equipment with a dry, ventilated, and temperature-appropriate environment.

- **Daily maintenance and care**: Regular maintenance of the advertising cutting machine, such as cleaning, lubrication, and inspection of parts, can timely discover and solve potential problems and extend the service life of the equipment. For example, regularly clean the dust and debris inside the equipment, check whether the laser lens is worn, etc.

- **Operation specifications**: Operate the advertising cutting machine correctly and in a standardized manner to avoid equipment damage due to misoperation. Operators should be familiar with the operating procedures and precautions of the equipment and operate in accordance with the requirements.

- **Work intensity**: The working intensity of the equipment will also affect its service life. If the advertising cutting machine runs at high load for a long time, it may accelerate the wear and aging of the equipment. Reasonable arrangement of the working tasks and time of the equipment and avoid excessive use can extend the life of the equipment.