- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

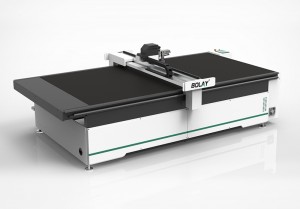

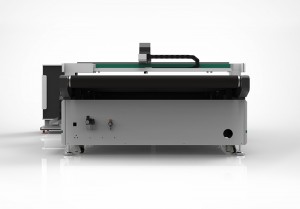

Gasket Cutting Machine | Digital Cutter

DESCRIPTION

The gasket cutting machine is a vibration knife cutting machine that can be widely used in various materials such as sealing ring gaskets, rubber, silicone, graphite, graphite composite gaskets, asbestos, asbestos-free materials, cork, PTFE, leather, composite materials, corrugated paper, car mats, car interiors, cartons, color boxes, soft PVC crystal pads, composite sealing ring materials, soles, cardboard, gray board, KT board, pearl cotton, sponge, and plush toys. The gasket cutting machine can achieve high precision and high speed, and more stably complete the special-shaped processing of seals. The finished workpiece has no sawtooth, no burrs, and is smooth with good consistency.

Video

Advantages

1. No need for mold data cutting

2. Intelligent layout, saving 20%+

3. Taiwan guide rail transmission, accuracy ±0.02mm

4. High-speed servo motor, production efficiency increased by more than four times

5. Interchangeable tools, easy cutting of hundreds of materials

6. Simple operation, ordinary workers can start work in 2 hours

7. Tungsten steel blade supports graphite metal gasket

8. Smooth cutting edge, no burrs

Equipment parameters

| Model | BO-1625 (Optional) |

| Optional type | Automatic feeding table |

| Maximum cutting size | 2500mm×1600mm (Customizable) |

| Overall size | 3571mm×2504mm×1325mm |

| Multi-function machine head | Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions (Optional) |

| Tool configuration | Electric vibration cutting tool, flying knife tool, milling tool, drag knife tool, slotting tool, etc. |

| Safety device | Infrared sensing, sensitive response, safe and reliable |

| Maximum cutting speed | 1500mm/s (depending on different cutting materials) |

| Maximum cutting thickness | 60mm (customizable according to different cutting materials) |

| Repeat accuracy | ±0.05mm |

| Cutting materials | Carbon fiber/prepreg, TPU/base film, carbon fiber cured board, glass fiber prepreg/dry cloth, epoxy resin board, polyester fiber sound-absorbing board, PE film/adhesive film, film/net cloth, glass fiber/XPE, graphite/asbestos/rubber, etc. |

| Material fixing method | Vacuum adsorption |

| Servo resolution | ±0.01mm |

| Transmission method | Ethernet port |

| Transmission system | Advanced servo system, imported linear guides, synchronous belts, lead screws |

| X, Y axis motor and driver | X axis 400w, Y axis 400w/400w |

| Z, W axis motor driver | Z axis 100w, W axis 100w |

| Rated power | 11kW |

| Rated voltage | 380V±10% 50Hz/60Hz |

Components of Composite material cutting machine

Multi-function machine head

Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions. The diversified machine head configuration can freely combine standard machine heads according to different processing requirements, and can flexibly respond to various production and processing requirements. (Optional)

Components of Composite material cutting machine

All-round safety protection

Emergency stop devices and safety infrared sensors are installed at all four corners to ensure maximum operator safety during high-speed movement of the machine.

Components of Composite material cutting machine

Intelligence brings high performance

High-performance cutter controllers are equipped with high-performance servo motors, intelligent, detail-optimized cutting technology and precise, maintenance-free drives. With excellent cutting performance, low operating costs and easy integration into production processes.

Sample of Gasket Cutting Machine

Energy consumption comparison

- Cutting Speed

- Cutting Accuracy

- Material Utilization Rate

- Cutting Cost

4-6 times + Compared with manual cutting, work efficiency is improved

Bolay machine speed

Manual cutting

High precision, high efficiency, and improved material utilization

Boaly Machine cutting accuracy

Punch cutting accuracy

Automatic typesetting system saves more than 20% of materials compared with manual typesetting

Bolay machine cutting efficiency

Manual cutting efficiency

Computer cutting, no need to open mold

Bolay machine cutting cost

Manual cutting cost

Product Introduction

-

Electric vibrating knife

-

Round knife

-

Pneumatic knife

-

V-groove cutting tool

Electric vibrating knife

Equipped with a wide variety of blades, it is suitable for processing different materials such as paper, cloth, leather and flexible composite materials.

– Fast cutting speed, smooth edges and cutting edges

Round knife

– Mainly used in clothing fabrics, suits, knitwear, underwear, wool coats, etc.

– Fast cutting speed, smooth edges and cutting edges

Pneumatic knife

– For materials that are soft, stretchable, and have high resistance, you can refer to them for multi-layer cutting.

– The amplitude can reach 8mm, and the cutting blade is driven by the air source to vibrate up and down.

V-groove cutting tool

②Three different cutting angles (0°, 30°, 45°, 60°)

③Fast blade replacement

Worry free service

-

Three year warranty

-

Free installation

-

Free training

-

Free maintenance

OUR SERVICES

-

01 /

Which materials can we cut?

The gasket cutting machine is a vibration knife cutting machine that can be widely used in sealing ring gaskets, rubber, silicone, graphite, graphite composite gaskets, asbestos, asbestos-free materials, cork, PTFE, leather, composite materials, corrugated paper, car mats, car interiors, cartons, color boxes, soft PVC crystal pads, composite sealing ring materials, soles, cardboard, gray board, KT board, pearl cotton, sponge, plush toys, and more. The gasket cutting machine can achieve high precision, high speed, and more stable completion of special-shaped processing of seals. The finished workpiece has no sawtooth, no burrs, and is smooth with good consistency.

-

02 /

What is the maximum cutting thickness?

The cutting thickness of the machine depends on the actual material. If cutting multi-layer fabric, it is suggested to be within 20 – 30mm. Please send me your material and thickness so that I can further check and give advice.

-

03 /

What is the machine cutting speed?

The machine cutting speed is 0 – 1500mm/s. The cutting speed depends on your actual material, thickness, and cutting pattern, etc.

-

04 /

What is the machine consumable part and lifetime?

This is related to your work time and operating experience.

-

05 /

Can the gasket cutting machine cut different materials at the same time?

In general, a gasket cutting machine may not be able to cut different materials at the same time in an optimal way.

Each material has its own unique properties such as hardness, thickness, and texture. The cutting parameters like cutting speed, pressure, and blade type are often optimized for specific materials. Trying to cut different materials simultaneously can lead to inconsistent cutting quality.

For example, a softer material like rubber may require less pressure and a different blade oscillation frequency compared to a harder material like graphite. If cut together, one material may be cut properly while the other may have issues such as rough edges, incomplete cuts, or even damage to the machine.

However, in some cases, if the materials have similar properties and the machine is properly adjusted and tested, it might be possible to cut certain combinations of materials with less than ideal results. But for high-quality and consistent cutting, it is recommended to cut one type of material at a time.

-

06 /

What are the main factors that affect the cutting quality of the gasket cutting machine?

The cutting quality of a gasket cutting machine is influenced by several main factors:

**1. Material properties**

- **Hardness**: Materials with different hardness levels require different cutting forces. Harder materials may cause more wear on the cutting tool and may need a stronger cutting action, which can affect the smoothness and accuracy of the cut.

- **Thickness**: Thicker materials can be more difficult to cut through evenly. The machine needs to have sufficient power and a proper cutting mechanism to handle thicker materials without causing uneven cuts or incomplete cuts.

- **Adhesiveness**: Some materials may be sticky or have adhesive properties, which can cause the blade to stick or drag during cutting, resulting in rough edges or inaccurate cuts.**2. Cutting tool condition**

- **Blade sharpness**: A dull blade will not cut cleanly and can leave ragged edges or burrs. Regular maintenance and replacement of the blade are essential to ensure good cutting quality.

- **Blade type**: Different materials may require specific types of blades. For example, a vibrating knife may be more suitable for certain soft materials, while a rotary blade may work better for thicker or tougher materials.

- **Blade wear**: Over time, the blade will wear down due to continuous use. Wear on the blade can affect the cutting accuracy and quality, so monitoring blade wear and replacing it when necessary is crucial.**3. Machine parameters**

- **Cutting speed**: The speed at which the machine cuts can have a significant impact on the quality of the cut. Too fast a cutting speed may result in incomplete cuts or rough edges, while too slow a speed can reduce productivity. Finding the optimal cutting speed for a particular material is important.

- **Pressure**: The amount of pressure applied by the cutting tool on the material needs to be adjusted according to the material’s properties. Insufficient pressure may not cut through the material properly, while excessive pressure can damage the material or the machine.

- **Vibration frequency**: In the case of a vibrating knife cutting machine, the vibration frequency can affect the cutting quality. Different materials may require different vibration frequencies to achieve the best results.**4. Operator skill and experience**

- **Programming accuracy**: The operator needs to input accurate cutting patterns and dimensions into the machine’s software. Errors in programming can lead to incorrect cuts and waste of materials.

- **Material handling**: Proper handling of the materials during loading and unloading can prevent damage to the material and ensure accurate positioning for cutting. An experienced operator will know how to handle different materials to minimize the risk of errors.

- **Maintenance and troubleshooting**: An operator who is familiar with the machine’s maintenance requirements and can troubleshoot problems quickly can help maintain the machine’s performance and cutting quality.**5. Environmental factors**

- **Temperature**: Extreme temperatures can affect the performance of the machine and the materials. Some materials may become more brittle or soft at different temperatures, which can impact the cutting quality.

- **Humidity**: High humidity can cause some materials to absorb moisture, which can affect their cutting properties. It can also lead to rust or corrosion on the machine’s metal parts.