Home Furnishing Cutting Machine | Digital Cutter

DESCRIPTION

The home furnishing cutting machine is a highly useful and advanced piece of equipment.

It is suitable for cutting a variety of materials such as leather, genuine leather, and different types of fabrics. The intelligent typesetting system and automatic cutting feature make the operation efficient and convenient. With the support of functions like one-key size change, automatic error compensation, and automatic marking, it greatly simplifies the cutting process and ensures accuracy.

By being able to replace 4 to 6 workers, it allows manufacturers to achieve significant cost savings at the root. The unique tool exchange system, which includes vibration knife, circular knife, marker pen, and punching, enables the realization of multiple processes with one machine. This versatility makes it a valuable asset for manufacturers dealing with different cutting and processing requirements.

The stable cutting and high cutting precision ensure the quality of the finished products, meeting the demanding standards of the home furnishing industry. Overall, this machine offers a comprehensive solution for home furnishing manufacturers, enhancing productivity and quality while reducing costs.

Video

Advantages

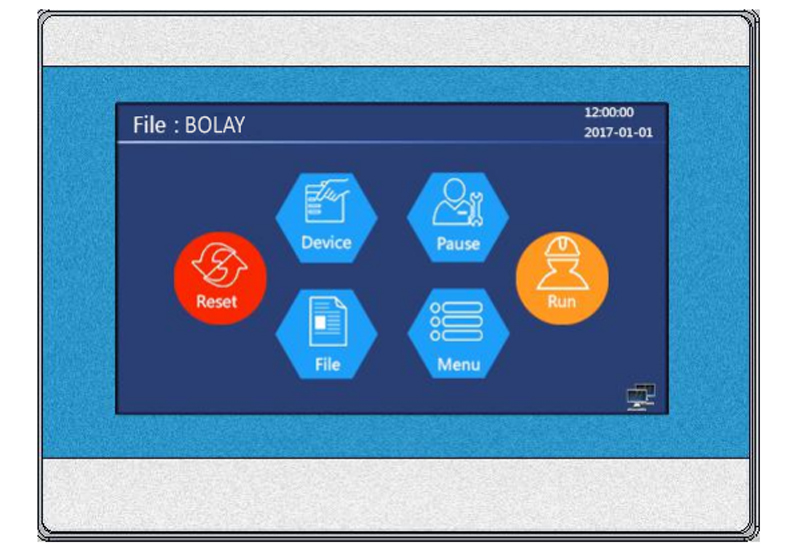

(1) Computer numerical control, automatic cutting, 7-inch LCD industrial touch screen, standard Dongling servo;

(2) High-speed spindle motor, the speed can reach 18,000 revolutions per minute;

(3) Any point positioning, cutting (vibrating knife, pneumatic knife, round knife, etc.), half-cutting (basic function), indentation, V-groove, automatic feeding, CCD positioning, pen writing (optional function);

(4) High-precision Taiwan Hiwin linear guide rail, with Taiwan TBI screw as the core machine base, to ensure accuracy and precision;

(6) Cutting blade material is tungsten steel from Japan

(7) Regin high-pressure vacuum pump, to ensure accurate positioning by adsorption

(8) The only one in the industry to use host computer cutting software, easy to install and simple to operate.

Equipment parameters

| Model | BO-1625 (Optional) |

| Maximum cutting size | 2500mm×1600mm (Customizable) |

| Overall size | 3571mm×2504mm×1325mm |

| Multi-function machine head | Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions (Optional) |

| Tool configuration | Electric vibration cutting tool, flying knife tool, milling tool, drag knife tool, slotting tool, etc. |

| Safety device | Infrared sensing, sensitive response, safe and reliable |

| Maximum cutting speed | 1500mm/s (depending on different cutting materials) |

| Maximum cutting thickness | 60mm (customizable according to different cutting materials) |

| Repeat accuracy | ±0.05mm |

| Cutting materials | Carbon fiber/prepreg, TPU/base film, carbon fiber cured board, glass fiber prepreg/dry cloth, epoxy resin board, polyester fiber sound-absorbing board, PE film/adhesive film, film/net cloth, glass fiber/XPE, graphite/asbestos/rubber, etc. |

| Material fixing method | vacuum adsorption |

| Servo resolution | ±0.01mm |

| Transmission method | Ethernet port |

| Transmission system | Advanced servo system, imported linear guides, synchronous belts, lead screws |

| X, Y axis motor and driver | X axis 400w, Y axis 400w/400w |

| Z, W axis motor driver | Z axis 100w, W axis 100w |

| Rated power | 11kW |

| Rated voltage | 380V±10% 50Hz/60Hz |

Components of Composite material cutting machine

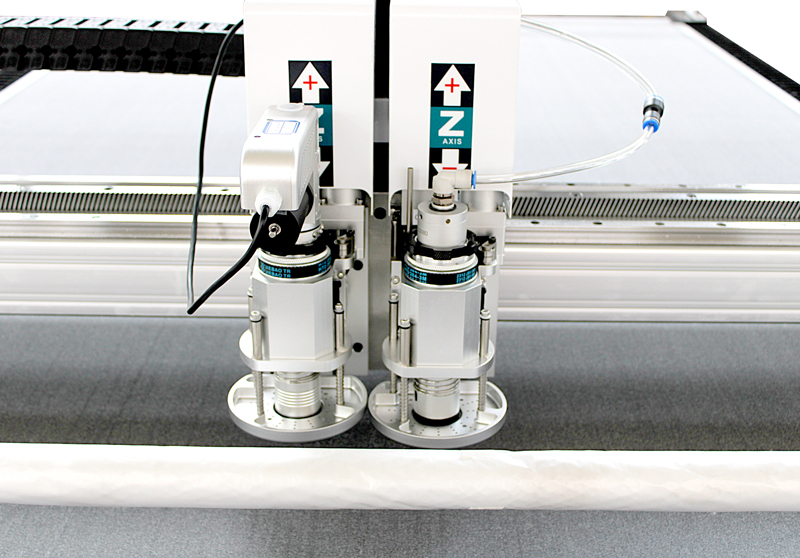

Multi-function machine head

Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions. The diversified machine head configuration can freely combine standard machine heads according to different processing requirements, and can flexibly respond to various production and processing requirements. (Optional)

Components of Composite material cutting machine

All-round safety protection

Emergency stop devices and safety infrared sensors are installed at all four corners to ensure maximum operator safety during high-speed movement of the machine.

Components of Composite material cutting machine

Intelligence brings high performance

High-performance cutter controllers are equipped with high-performance servo motors, intelligent, detail-optimized cutting technology and precise, maintenance-free drives. With excellent cutting performance, low operating costs and easy integration into production processes.

Sample of Home Furnishing Cutting Machine

Energy consumption comparison

- Cutting Speed

- Cutting Accuracy

- Material Utilization Rate

- Cutting Cost

4-6 times + Compared with manual cutting, work efficiency is improved

Bolay machine speed

Manual cutting

High precision, high efficiency, and improved material utilization

Boaly Machine cutting accuracy

Manual cutting accuracy

Automatic typesetting system saves more than 20% of materials compared with manual typesetting

Bolay machine cutting efficiency

Manual cutting efficiency

No smoke and dust, high precision, high efficiency, saving time and effort

Bolay machine cutting cost

Manual cutting cost

Product Introduction

-

Electric vibrating knife

-

Round knife

-

Pneumatic knife

Electric vibrating knife

Equipped with a wide variety of blades, it is suitable for processing different materials such as paper, cloth, leather and flexible composite materials.

– Fast cutting speed, smooth edges and cutting edges

Round knife

– Mainly used in clothing fabrics, suits, knitwear, underwear, wool coats, etc.

– Fast cutting speed, smooth edges and cutting edges

Pneumatic knife

– For materials that are soft, stretchable, and have high resistance, you can refer to them for multi-layer cutting.

– The amplitude can reach 8mm, and the cutting blade is driven by the air source to vibrate up and down.

Worry free service

-

Three year warranty

-

Free installation

-

Free training

-

Free maintenance

OUR SERVICES

-

01 /

Which materials can we cut?

The home furnishing cutting machine is suitable for cutting leather, genuine leather, fabric, and other fabrics. It features an intelligent typesetting system, automatic cutting, and supports functions like one-key size change, automatic error compensation, and automatic marking.

-

02 /

What is the machine's consumable part and lifetime?

The consumable parts and lifetime of the machine depend on factors such as your work time and operating experience. Generally, cutting tools may be considered consumable parts. The lifetime can vary greatly depending on proper maintenance and usage. Regular maintenance and following the manufacturer’s guidelines can extend the machine’s lifespan.

-

03 /

What is the machine cutting speed?

The machine cutting speed is 0 – 1500mm/s. The actual cutting speed depends on your material, thickness, and cutting pattern.

-

04 /

How do I choose a suitable cutting tool to finish?

The machine comes with different cutting tools. Please tell me your cutting material and provide sample pictures, and I will give you advice on choosing the most suitable cutting tool.

-

05 /

Can the home furnishing cutting machine be customized according to specific needs?

Yes, the home furnishing cutting machine can often be customized according to specific needs.

Manufacturers usually offer customization options to meet the diverse requirements of different customers. For example, you can customize the machine size to fit your workspace. The color of the machine can also be adjusted to match your production environment or brand identity.

In addition, some manufacturers may be able to customize specific features based on your unique production processes. This could include modifications to the cutting tools, the typesetting system, or the automation functions to better suit your particular materials and production needs.

If you have specific requirements, it is advisable to contact our directly to discuss your customization options and determine if they can meet your needs.