- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

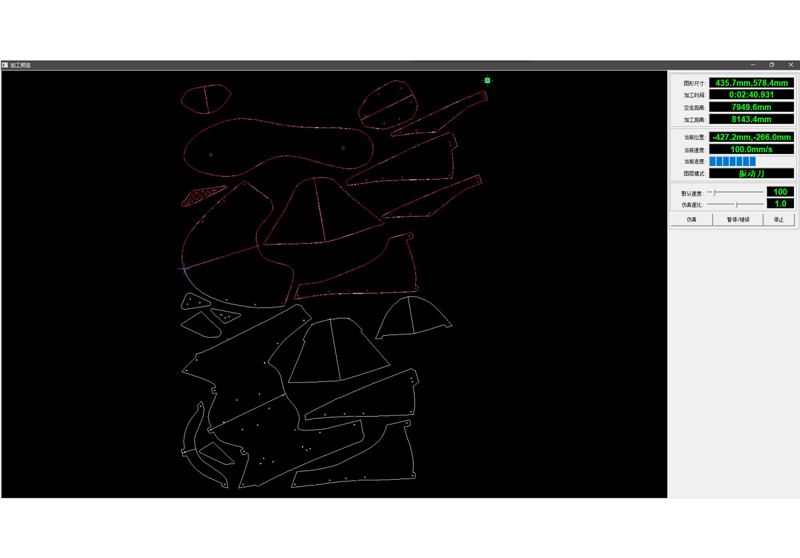

Leather Cutting Machine | Digital Cutter

DESCRIPTION

The leather cutting machine is a vibrating knife cutting machine that finds extensive application in non-metallic materials with a thickness not exceeding 60mm. This includes a diverse range of materials such as genuine leather, composite materials, corrugated paper, car mats, car interiors, cartons, color boxes, soft PVC crystal pads, composite sealing materials, soles, rubber, cardboard, gray board, KT board, pearl cotton, sponge, and plush toys.

Video

Advantages

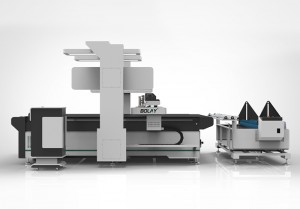

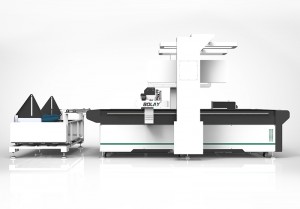

1. Scanning-layout-cutting all-in-one machine

2. Provide cutting of whole leather materials

3. Continuous cutting, saving manpower, time and materials

4. Gantry finishing frame, more stable

5. Double beams and double heads work asynchronously, double the efficiency

6. Automatic layout of irregular materials

7. Improve material utilization

Equipment parameters

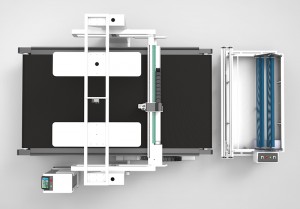

| Model | BO-1625 |

| Effective cutting area (L*W) | 2500*1600mm | 2500*1800mm | 3000*2000mm |

| Appearance size (L*W) | 3600*2300mm |

| Special size | customizable |

| Cutting tools | vibration knife, drag knife, half knife, drawing pen, cursor, pneumatic knife, flying knife, pressure wheel, V-groove knife |

| Safety device | physical anti-collision mechanism + infrared induction anti-collision to ensure production safety |

| Cutting thickness | 0.2-60mm (customizable height) |

| Cutting materials | cloth, leather, photovoltaic panels, corrugated paper, advertising materials and other materials |

| Cutting speed | ≤1200mm/s (actual speed depends on the material and the cutting pattern) |

| Cutting accuracy | ±0.1mm |

| Repeat accuracy | ≦0.05mm |

| Cutting circle diameter | ≧2mm diameter |

| Positioning method | laser light positioning and large visual positioning |

| Material fixing method | vacuum adsorption, optional intelligent multi-zone vacuum adsorption and follow-up adsorption |

| Transmission interface | Ethernet port |

| Compatible software format | AI software, AutoCAD, CorelDRAW and all box design software can be directly output without conversion, and with automatic optimization |

| Instruction system | DXF, HPGL compatible format |

| Operation panel | multi-language LCD touch panel |

| Transmission system | high-precision linear guide, precision gear rack, high-performance servo motor and driver |

| Power supply voltage | AC 220V 380V ±10%, 50HZ; whole machine power 11kw; fuse specification 6A |

| Air pump power | 7.5KW |

| Working environment | temperature: -10℃~40℃, humidity: 20%~80%RH |

Components of Composite material cutting machine

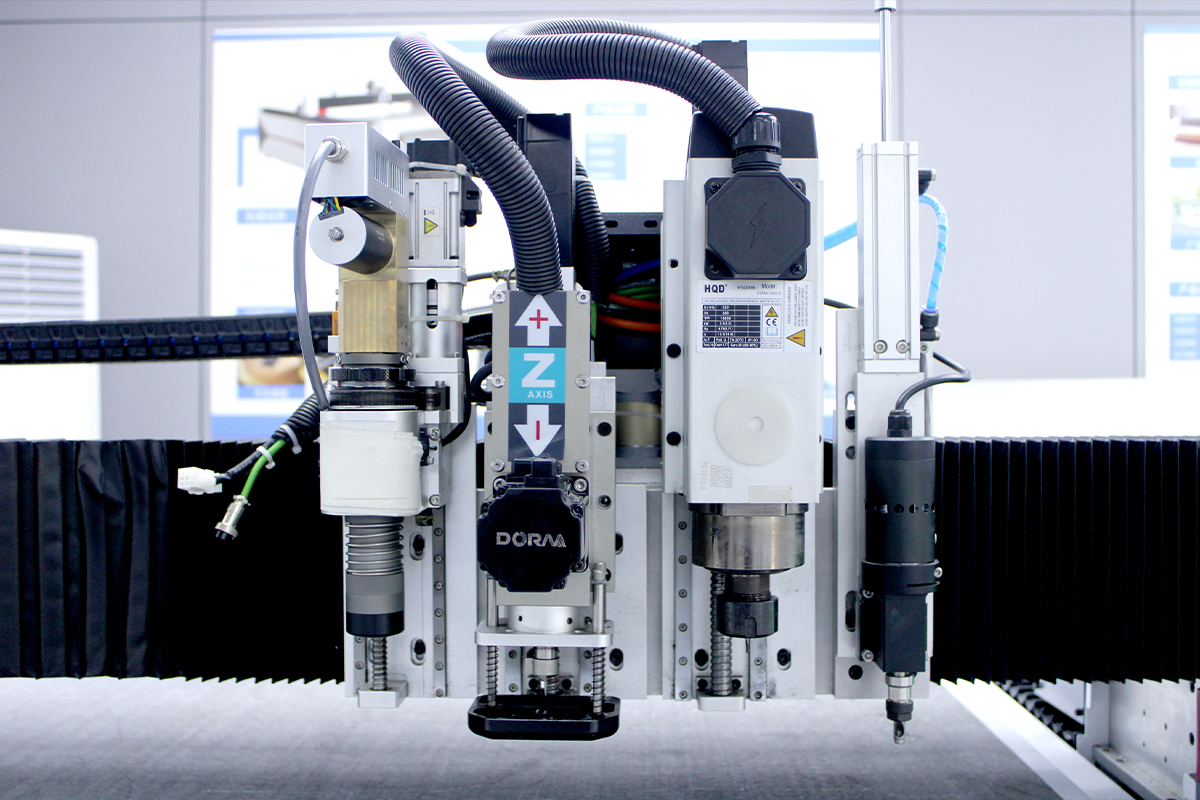

Multi-function machine head

Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions. The diversified machine head configuration can freely combine standard machine heads according to different processing requirements, and can flexibly respond to various production and processing requirements. (Optional)

Components of Composite material cutting machine

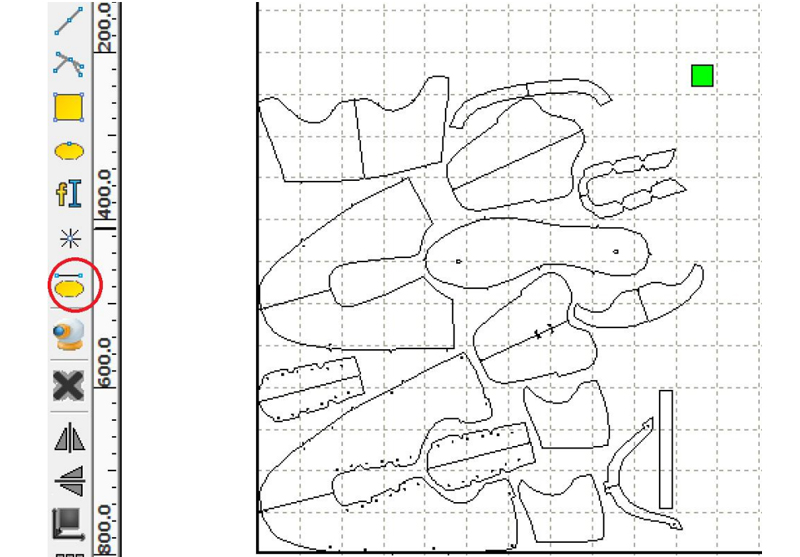

Smart nesting system

This feature is more reasonable compared with the normal patterms arranging.It’s easier to operate and waste saving.it’s capable of arranging odd number of pattems, cutting leftover materials and dividedcutting of large pattem.

Components of Composite material cutting machine

Projector positioning system

Instant Preview of Nesting Effects -convenient, fast.

Components of Composite material cutting machine

Defect Detecting Function

For Genuine leather, this function can automatic detect and avoid defect on the leather during nesting and cutting,the utilization rate of genuine leather canreach between85-90%, save the material.

Sample of Leather Cutting Machine

Energy consumption comparison

- Cutting Speed

- Cutting Accuracy

- Material Utilization Rate

- Cutting Cost

4-6 times + Compared with manual cutting, work efficiency is improved

Bolay machine speed

Manual cutting

High precision, high efficiency, and improved material utilization.

Boaly Machine cutting accuracy

Manual cutting accuracy

The equipment system contains automatic typesetting software, which supports the calculation of material utilization rate, which is more than 15% higher than manual typesetting.

Bolay machine cutting efficiency

Manual cutting efficiency

The equipment has no other consumption except electricity and operator wages. One device can replace 4-6 workers and basically pay back the investment in half a year.

Bolay machine cutting cost

Manual cutting cost

Product Introduction

-

Electric vibrating knife

-

Round knife

-

Pneumatic knife

-

Punching

Electric vibrating knife

Equipped with a wide variety of blades, it is suitable for processing different materials such as paper, cloth, leather and flexible composite materials.

– Fast cutting speed, smooth edges and cutting edges

Round knife

– Mainly used in clothing fabrics, suits, knitwear, underwear, wool coats, etc.

– Fast cutting speed, smooth edges and cutting edges

Pneumatic knife

– For materials that are soft, stretchable, and have high resistance, you can refer to them for multi-layer cutting.

– The amplitude can reach 8mm, and the cutting blade is driven by the air source to vibrate up and down.

Punching

-Punching range: 0.8mm-5mm optional

-Fast punching speed, smooth edges

Worry free service

-

Three year warranty

-

Free installation

-

Free training

-

Free maintenance

OUR SERVICES

-

01 /

Which materials can be cut?

The machine is suitable for cutting various materials such as all kinds of genuine leather, artificial leather, upper materials, synthetic leather, saddle leather, shoe leather, sole materials and others. It also has replaceable blades for cutting other flexible materials. It is widely used for cutting special-shaped materials like leather shoes, bags, leather clothes, leather sofas and more. The equipment operates through computer-controlled blade cutting, with automatic typesetting, automatic cutting, and automatic loading and unloading, enhancing material utilization and maximizing material savings.

-

02 /

What is the maximum cutting thickness?

The cutting thickness of the machine depends on the actual material. If cutting multi-layer fabric, please provide more details so that I can further check and give advice.

-

03 /

What is the machine cutting speed?

The machine cutting speed ranges from 0 to 1500mm/s. The cutting speed depends on your actual material, thickness, and cutting pattern, etc.

-

04 /

Can I customize?

Yes, we can help you design and customize the machine in terms of size, color, brand, etc. Please tell us your specific needs.

-

05 /

About delivery terms

We accept both air shipping and sea shipping. Accepted delivery terms include EXW, FOB, CIF, DDU, DDP, and express delivery, etc.

-

06 /

How thick leather can the leather cutting machine cut?

The cutting thickness of the leather cutting machine depends on the actual leather material and other factors. Generally speaking, if it is a single layer of leather, it can usually cut thicker leather, and the specific thickness may range from a few millimeters to more than ten millimeters.

If it is multi-layer leather superposition cutting, its thickness is recommended to be considered according to different machine performance, which may be around 20 mm to 30 mm, but the specific situation needs to be further determined by combining the performance parameters of the machine and the hardness and texture of the leather. At the same time, you can consult us directly and we will give you a suitable recommendation.