- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

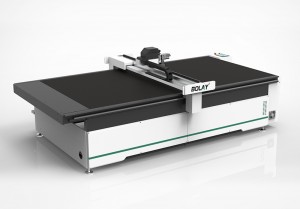

Packaging Industry Cutting Machine | Digital Cutter

DESCRIPTION

BolayCNC is a remarkable intelligent digital cutting equipment designed specifically for proofing and small batch customized production in the packaging and printing industries.

The packaging industry cutting machine has a wide range of applicable materials, including pearl cotton, KT board, self-adhesive, hollow board, corrugated paper, and more. This versatility makes it a valuable tool for businesses dealing with various packaging materials.

The adoption of computer cutting technology enables the machine to quickly and accurately complete multiple processes such as full cutting, half cutting, creasing, beveling, punching, marking, and milling. Having all these functions on one machine streamlines the production process and saves time and space.

This cutting machine empowers customers to process accurate, novel, unique, and high-quality products more quickly and conveniently. It meets the demands of today’s market for customized packaging solutions and helps businesses stand out in a competitive industry.

With its advanced features and capabilities, BolayCNC is a game-changer in the packaging and printing industries, driving innovation and efficiency.

Video

Advantages

1. One machine has multiple functions, batch processing of different materials, short orders, fast response, and fast delivery.

2. Reduce labor, one worker can operate multiple devices at the same time, equipped with typesetting and imposition functions, improving efficiency and achieving significant cost optimization results.

3. One person can operate multiple devices at the same time, equipped with typesetting and imposition functions, and the cost optimization results are significant.

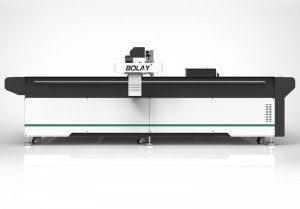

4. Computer numerical control, automatic cutting, 7-inch LCD industrial touch screen, standard Dongling servo;

5. High-speed spindle motor, the speed can reach 18,000 revolutions per minute;

6. Any point positioning, cutting (vibrating knife, pneumatic knife, round knife, etc.), half-cutting (basic function), indentation, V-groove, automatic feeding, CCD positioning, pen writing (optional function);

7. High-precision Taiwan Hiwin linear guide rail, with Taiwan TBI screw as the core machine base, to ensure accuracy and precision;

8. Cutting blade material is tungsten steel from Japan

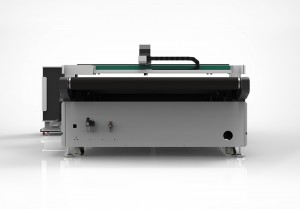

9. Regin high-pressure vacuum pump, to ensure accurate positioning by adsorption

10. The only one in the industry to use host computer cutting software, easy to install and simple to operate.

Equipment parameters

| Model | BO-1625 (Optional) |

| Maximum cutting size | 2500mm×1600mm (Customizable) |

| Overall size | 3571mm×2504mm×1325mm |

| Multi-function machine head | Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions (Optional) |

| Tool configuration | Electric vibration cutting tool, flying knife tool, milling tool, drag knife tool, slotting tool, etc. |

| Safety device | Infrared sensing, sensitive response, safe and reliable |

| Maximum cutting speed | 1500mm/s (depending on different cutting materials) |

| Maximum cutting thickness | 60mm (customizable according to different cutting materials) |

| Repeat accuracy | ±0.05mm |

| Cutting materials | Carbon fiber/prepreg, TPU/base film, carbon fiber cured board, glass fiber prepreg/dry cloth, epoxy resin board, polyester fiber sound-absorbing board, PE film/adhesive film, film/net cloth, glass fiber/XPE, graphite/asbestos/rubber, etc. |

| Material fixing method | vacuum adsorption |

| Servo resolution | ±0.01mm |

| Transmission method | Ethernet port |

| Transmission system | Advanced servo system, imported linear guides, synchronous belts, lead screws |

| X, Y axis motor and driver | X axis 400w, Y axis 400w/400w |

| Z, W axis motor driver | Z axis 100w, W axis 100w |

| Rated power | 11kW |

| Rated voltage | 380V±10% 50Hz/60Hz |

Components of Composite material cutting machine

Multi-function machine head

Dual tool fixing holes, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting and other functions. The diversified machine head configuration can freely combine standard machine heads according to different processing requirements, and can flexibly respond to various production and processing requirements. (Optional)

Components of Composite material cutting machine

All-round safety protection

Emergency stop devices and safety infrared sensors are installed at all four corners to ensure maximum operator safety during high-speed movement of the machine.

Components of Composite material cutting machine

Intelligence brings high performance

High-performance cutter controllers are equipped with high-performance servo motors, intelligent, detail-optimized cutting technology and precise, maintenance-free drives. With excellent cutting performance, low operating costs and easy integration into production processes.

Sample of Packaging Industry Cutting Machine

Energy consumption comparison

- Cutting Speed

- Cutting Accuracy

- Material Utilization Rate

- Cutting Cost

4-6 times + Compared with manual cutting, work efficiency is improved

Bolay machine speed

Manual cutting

Cutting, slotting, punching, marking, milling functions

Boaly Machine cutting accuracy

Manual cutting accuracy

Automatic edge-finding and special-shaped cutting, one-click cutting of various materials

Bolay machine cutting efficiency

Manual cutting efficiency

No smoke and dust, high precision, high efficiency

Bolay machine cutting cost

Manual cutting cost

Product Introduction

-

Electric vibrating knife

-

V-groove cutting tool

-

Pneumatic knife

-

Pressing wheel

Electric vibrating knife

Equipped with a wide variety of blades, it is suitable for processing different materials such as paper, cloth, leather and flexible composite materials.

– Fast cutting speed, smooth edges and cutting edges

V-groove cutting tool

Pneumatic knife

– For materials that are soft, stretchable, and have high resistance, you can refer to them for multi-layer cutting.

– The amplitude can reach 8mm, and the cutting blade is driven by the air source to vibrate up and down.

Pressing wheel

- Reduce wrinkling or tearing of the material.

- Precisely control the indentation depth, change different pressing wheel sizes and styles according to different materials, easy to change

Worry free service

-

Three year warranty

-

Free installation

-

Free training

-

Free maintenance

OUR SERVICES

-

01 /

Which materials can we cut?

The packaging industry cutting machine is applicable to various materials such as pearl cotton, KT board, self-adhesive, hollow board, corrugated paper, etc. It adopts computer cutting and can quickly and accurately complete full cutting, half cutting, creasing, beveling, punching, marking, milling, and other processes, all on one machine.

-

02 /

What is the maximum cutting thickness?

The cutting thickness depends on the actual material. For multi-layer fabric, it is suggested to be within 20 – 30mm. If cutting foam, it is suggested to be within 100mm. You can send your material and thickness for further checking and advice.

-

03 /

What is the machine warranty?

The machine comes with a 3-year warranty (excluding consumable parts and damage caused by human factors).

-

04 /

What is the machine cutting speed?

The machine cutting speed is 0 – 1500mm/s. The cutting speed depends on your actual material, thickness, and cutting pattern.

-

05 /

What are the advantages of using a packaging industry cutting machine?

Using a packaging industry cutting machine offers several significant advantages:

**1. Versatility in materials**:

- Can handle a wide range of materials such as pearl cotton, KT board, self-adhesive, hollow board, corrugated paper, and more. This allows businesses to process different types of packaging materials without the need for multiple specialized machines.**2. Multiple functions in one machine**:

- It can perform full cutting, half cutting, creasing, beveling, punching, marking, and milling all on a single machine. This reduces the need for separate machines for each process, saving space and reducing equipment investment costs.**3. High precision and accuracy**:

- Computer-controlled cutting ensures precise cuts and consistent results. This is crucial for producing high-quality packaging that meets strict specifications and enhances the overall appearance and functionality of the packaging.**4. Speed and efficiency**:

- The machine can quickly complete various cutting and processing tasks, increasing production throughput. This is especially beneficial for businesses with tight deadlines or high-volume production requirements.**5. Customization capabilities**:

- Ideal for proofing and small batch customized production. It allows businesses to create unique and personalized packaging designs to meet specific customer needs and stand out in the market.**6. Cost savings**:

- By reducing the need for multiple machines and manual labor, it can lead to significant cost savings in the long run. Additionally, the high precision and efficiency of the machine can reduce material waste and improve overall productivity.**7. Easy operation and programming**:

- Modern packaging industry cutting machines often come with user-friendly interfaces and software that make it easy for operators to program and control the cutting processes. This reduces the learning curve and increases operational efficiency.6.Can the packaging industry cutting machine be customized to meet specific production requirements?

Yes, the packaging industry cutting machine can often be customized to meet specific production requirements.Manufacturers may offer various customization options to accommodate different needs. For example:

- **Size and dimensions**: The machine can be customized to fit specific workspace constraints or to handle larger or smaller packaging materials.

- **Cutting capabilities**: Customization can include adjusting the cutting speed, precision, and thickness capacity to match the specific requirements of the materials being processed.

- **Functionality**: Additional features such as specific types of cutting tools, creasing or perforating options, or specialized marking systems can be added to meet unique production processes.

- **Automation and integration**: The machine can be integrated with other production equipment or automated systems to improve efficiency and streamline the production line.

- **Software and controls**: Custom software interfaces or programmable controls can be developed to meet specific workflow requirements and optimize the cutting process.By working with us, we can discuss their specific production needs and explore customization options to ensure the packaging industry cutting machine is tailored to their unique requirements.