- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Umshini wokusika wokukhangisa | Umsiki wedijithali

Ukufanisa

Uhlelo lokunciphisa lokusika lomshini wokukhangisa luwukusungulwa okumangazayo. Ngokuhlanganisa izinzuzo ezintathu ezibalulekile zokusebenza, ijubane, nekhwalithi, inikeza isixazululo esinamandla somkhakha wokukhangisa.

Ukubambisana namathuluzi ama-modular akuvumela ukuthi ahlangabezane nezidingo zabasebenzisi ezenziwe ngezifiso. Lokhu kuguquguquka kwenza ukuthi umshini uvumelane nezindlela eziningi zokukhangisa. Noma ngabe ukusika okugcwele, ukusika okugcwele, ukugaya, ukubhoboza, ukudala ukukhishwa, noma ukumaka, uhlelo lungasheshe luqede izinqubo ezahlukahlukene. Ukuba nayo yonke le misebenzi emshinini owodwa kuyinzuzo enkulu njengoba isindisa isikhala futhi ihambisa ukuhamba komsebenzi wokukhiqiza.

Lo mshini unika abasebenzisi amandla okucubungula inoveli, imikhiqizo ehlukile yokukhangisa ekhwalithi ngokushesha okukhulu nangokunembile ngesikhathi esilinganiselwe nendawo. Ngokwenza kanjalo, kuthuthukisa kahle ukuncintisana kwemboni kwabasebenzisi bokukhiqiza abakhangisayo. Kuyabasiza ukuthi baphume emakethe ngokwakha imikhiqizo ekhethekile yokukhangisa edonsela ukunaka futhi idlulise imiyalezo yomkhiqizo ngempumelelo. Ekugcineni, isiza abasebenzisi ekuzuzeni ukwamukelwa okuhle kakhulu kanye nempumelelo.

Ividiyo

Izinzuzo

1. Umshini wokusika wokukhangisa ungacubungula izixazululo ezahlukahlukene zesiginali, njengezimpawu zama-facade noma amafasitela ezitolo ezinkulu, amafulegi amabhanela, umshini wezindwangu, umshini wokusika ukuhlinzeka ngemiqondo eqondene nomuntu -Ukusebenzisana nokusika okusebenzayo kwezinto zokukhangisa zezindwangu.

2. Umshini wokusika wokukhangisa ungakunikeza ngezixazululo ezenziwe ngezifiso zezidingo zakho ngokusebenzisa amathuluzi wesoftware asungulayo nobuchwepheshe besimanje bedijithali.

3. Noma ngabe kuyingxenye yokusika noma ukusika ngokwemodeli yokugcina, umshini wokusika wokukhangisa ungahlangabezana nezidingo eziphakeme kakhulu zokunemba, ikhwalithi nokusebenza kahle kokukhiqiza.

Imingcele yemishini

| Isifanekiso | I-Bo-1625 (Ngokuzithandela) |

| Ubukhulu obuphezulu bokusika | I-2500mm × 1600mm (ngokwezifiso) |

| Usayizi ophelele | 3571mm × 2504mm × 1325mm |

| Inhloko yomshini womsebenzi omningi | Ithuluzi elimbaxambili lokulungisa amathuluzi, ithuluzi lokufaka okusheshayo kokuhlela, ukufakwa kwamathuluzi okusheshayo futhi okusheshayo kwamathuluzi okusika, ipulaki nokudlala, ukuhlanganisa ukusika, ukugaya, ukuvala kanye neminye imisebenzi (ngokuzithandela) |

| Ukucushwa kwamathuluzi | Ithuluzi lokusika eli-Electric Vibration, ithuluzi elindiza ummese, ithuluzi lokugaya, ithuluzi lokuvikela i-knife, ithuluzi lokuvala, njll. |

| Idivaysi yokuphepha | Ukuzwakala okungenampilo, impendulo ebucayi, iphephile futhi ithembekile |

| Isivinini esikhulu sokusika | I-1500mm / s (kuya ngezinto ezahlukahlukene zokusika) |

| Ubukhulu bokusika | I-60mm (ngokwezifiso ngokuya ngezinto ezihlukile zokusika) |

| Phinda ukunemba | ± 0.05mm |

| Izinto zokusika | I-Carbon Fibre / i-PrePreg, i-TPU / Base ifilimu, ibhodi le-carbon fiber curreg / indwangu eyomile, i-polyester redin film, ifilimu / indwangu yefilimu / i-file / indwangu ye-glass / xpe, graphite / Asbestos / irabha, njll. |

| Indlela yokulungisa izinto ezibonakalayo | vacuum adsorption |

| Ukulungiswa kwe-servo | ± 0.01mm |

| Indlela yokuhambisa | I-Ethernet Port |

| Isistimu yokuhambisa | Uhlelo lweSerso oluthuthukisiwe, imihlahlandlela eqondile engenisiwe, amabhande avumelanayo, izikulufo eziholayo |

| X, y axis motor nomshayeli | X axis 400W, y Axis 400W / 400W |

| Z, w axis motor driver | Z axis 100w, w axis 100w |

| Amandla alinganiselwe | 11kw |

| Amandla kagesi | 380v ± 10 50hz / 60hz |

Izingxenye zomshini wokusika wezinto ezibonakalayo

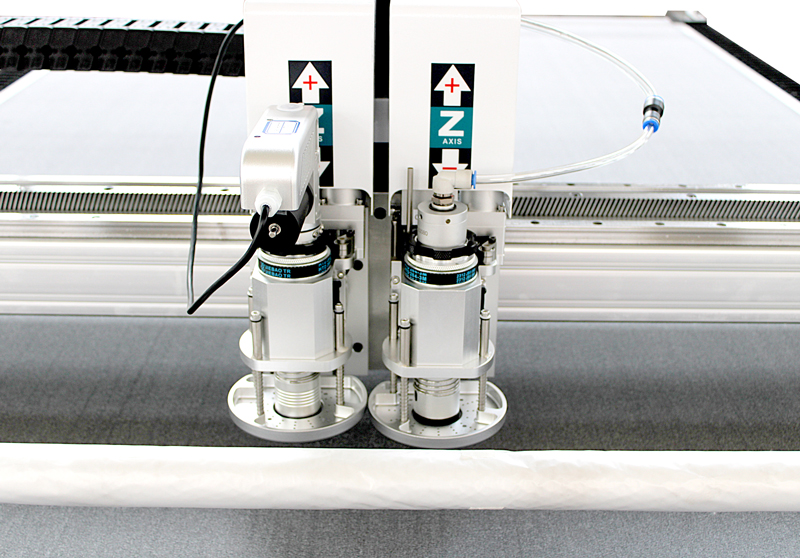

Inhloko yomshini womsebenzi omningi

I-Dual Tool Fingting Holes, ithuluzi lokufaka okusheshayo kokuhlela, ukufakwa kwamathuluzi okusheshayo futhi okusheshayo kwamathuluzi okusika, ipulaki kanye nokudlala, ukuhlanganisa ukusika, ukugaya, ukuvala kanye neminye imisebenzi. Ukucushwa kwekhanda ngomshini okuhlukahlukene kungahlanganisa ngokukhululeka amakhanda womshini ejwayelekile ngokuya ngezidingo ezahlukahlukene zokucubungula, futhi angaphendula kalula ekukhiqizeni okuhlukahlukene kanye nezidingo zokucubungula. (Ngokuzithandela)

Izingxenye zomshini wokusika wezinto ezibonakalayo

Ukuvikelwa Kokuphepha Okuzungezile

Amadivayisi okuma eziphuthumayo kanye nezinzwa ze-infrared yezokuphepha zifakiwe kuwo wonke amakhona amane ukuqinisekisa ukuphepha okuphezulu komhlinzeki ngesikhathi sokuhamba ngejubane elikhulu lomshini.

Izingxenye zomshini wokusika wezinto ezibonakalayo

Ubuhlakani buletha ukusebenza okuphezulu

Abalawuli abasebenza ngokusebenza okuphezulu bahlome ngama-motor e-serso asebenza kakhulu, ubuchwepheshe obuhlakaniphile, obuhleliwe obuhleliwe kanye nemininingwane eqondile, yokushayela. Ngokusebenza okuhle kakhulu kokusika, izindleko ezisebenzayo zokusebenza kanye nokuhlanganiswa okulula kwezinqubo zokukhiqiza.

Isampula yomshini wokusika wokukhangisa

Ukuqhathaniswa kokusetshenziswa kwamandla

- Isivinini sokusika

- Ukusika ukunemba

- Izinga lokusetshenziswa kwezinto ezibonakalayo

- Ukusika izindleko

Izikhathi ezi-4-6 + ziqhathaniswa nokusika okwenziwa ngesandla, ukusebenza kahle komsebenzi kuyathuthukiswa

Ijubane lomshini we-Bolay

Ukusika okwenziwa ngesandla

Ukunemba okuphezulu, ukusebenza kahle okuphezulu, kanye nokusetshenziswa okungcono kwezinto

I-BOALY SCHINETING CUSTINCY ukunemba

Ukunemba kokusika okwenziwe ngesandla

Uhlelo oluzenzakalelayo lokuthayela lusindisa ngaphezulu kwama-20% wezinto zokwakha uma kuqhathaniswa nokuhlelwa kwamagama

Ukusebenza Komshini Wokusika

Ukusebenza kahle kweManual

Izindleko zokusika umshini we-Bolay

Izindleko zokusika ngesandla

Isingeniso Somkhiqizo

-

I-Electric Vibrating Knife

-

Ummese oyindilinga

-

Ummese we-pneumatic

I-Electric Vibrating Knife

Ihlotshiswe ngezinhlobonhlobo zama-blade, kufanelekile ukucubungula izinto ezahlukahlukene ezifana nephepha, indwangu, isikhumba nezinto eziguqukayo zenhlanganisela.

- Isivinini sokusika okusheshayo, imiphetho ebushelelezi namaphethelo wokusika

Ummese oyindilinga

- Isetshenziswa ikakhulukazi ezindwangu zokugqoka, amasudi, ama-knitwear, ngaphansi kwezingubo zangaphansi, amajazi oboya, njll.

- Isivinini sokusika okusheshayo, imiphetho ebushelelezi namaphethelo wokusika

Ummese we-pneumatic

- Kwezinto zokwenziwa ezithambile, zeluliwe, futhi zinokumelana okuphezulu, ungabhekisa kubo ngokusika kwengqimbanhlobo.

- I-amplitude ingafinyelela ku-8mm, futhi ibala lokusika liqhutshwa umthombo womoya ukuze udlidlize phezulu naphansi.

Insiza yamahhala

-

Iwaranti yeminyaka emithathu

-

Ukufakwa kwamahhala

-

Ukuqeqeshwa kwamahhala

-

Ukulungiswa kwamahhala

Izinsizakalo zethu

-

01 /

Yiziphi izinto ezingasinquma?

Umshini wokusika wokukhangisa ungacubungula izinhlelo ezahlukahlukene zezimpawu, kufaka phakathi izimpawu zesitolo sangaphambili noma izitolo zewindi, izimpawu zokufaka izimoto, izimpawu ezithambile, amalebula abonisa amasayizi ahlukene namamodeli.

-

02 /

Yibuphi ubukhulu bokusika okukhulu?

Ubukhulu bokusika bomshini buxhomekeke kokuqukethwe kwangempela. Uma usika indwangu ehlukahlukene ehlukahlukene, kuphakanyiswa ukuthi ube ngaphakathi kwama-20 - 30mm. Uma ukusika igwebu, kuphakanyiswa ukuba phakathi kwe-100mm. Ngicela ungithumele okuqukethwe kwakho nobukhulu ukuze ngikwazi ukuqhubeka nokuhlola futhi nginikeze izeluleko.

-

03 /

Yini ijubane lomshini lokusika?

Isivinini sokusika ngomshini singu-0 - 1500mm / s. Isivinini sokusika sincike kokuqukethwe kwakho kwangempela, ubukhulu, kanye nokusika iphethini, njll.

-

04 /

Yini iwaranti yomshini?

Umshini unewaranti yeminyaka emi-3 (hhayi kufaka phakathi izingxenye ezisebenzayo kanye nomonakalo womuntu).

-

05 /

Isikhathi esingakanani senkonzo yomshini wokusika wokukhangisa?

Impilo yenkonzo yomshini wokusika wokukhangisa ngokuvamile cishe iminyaka eyi-8 kuye kweli-15, kepha izohluka ngokuya ngezinto ezahlukahlukene.

Okulandelayo ezinye izinto ezithinta impilo yenkonzo yomshini wokusika wokukhangisa:

- ** Ikhwalithi Yemishini kanye Nobubanzi:

- ** Sebenzisa Imvelo **: Uma umshini wokusika wokukhangisa usetshenziswa endaweni enokhahlo, njengokushisa okuphezulu, umswakama, uthuli, njll. Ngakho-ke, kuyadingeka ukuhlinzeka ngemishini ngemvelo eyomile, enomoya, nefanele yokushisa.

- ** Ukulungiswa kwansuku zonke kanye nokunakekelwa ** Isibonelo, hlanza njalo uthuli kanye nemfucumfucu ngaphakathi kwemishini, hlola ukuthi ngabe ilensi ye-laser igqokwa, njll.

- ** Ukucaciswa Ukucaciswa **: Sebenzisa umshini wokusika wokukhangisa ngendlela efanele nangendlela esezingeni elifanele ukugwema ukulimala kwemishini ngenxa yokusebenza kabi. Ama-opharetha kufanele ajwayelene nezinqubo zokusebenza kanye nokuphepha kwemishini futhi asebenze ngokuya ngezidingo.

- ** Umsebenzi Wokuqina **: Ukuqina okusebenzayo kwemishini kuzothinta nempilo yayo yenkonzo. Uma umshini wokusika wokukhangisa ugijimisa umthwalo omkhulu isikhathi eside, ungasheshisa ukugqoka nokuguga kwemishini. Ukuhlelwa okunengqondo kwemisebenzi esebenzayo nesikhathi semishini futhi kugweme ukusetshenziswa ngokweqile kunganweba impilo yemishini.