- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

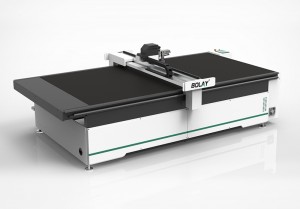

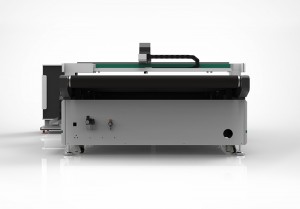

Umshini wokusika we-gasket | Umsiki wedijithali

Ukufanisa

Umshini wokusika we-gasket ngumshini wokusika ummese wokuvinjwa ongasetshenziswa kabanzi ezindaweni ezahlukahlukene ezifana nama-gaskets e-barning ring, irabha, i-asbestos, i-asbestos-free workes, ukhokho, i-PTFE, isikhumba, iphepha elihlanganisiwe, amakati ezimoto, ama-cartoors emoto, amabhokisi, amabhokisi ezinhlamvu, ama-porting pvc crystal pads, ama-soled endandatho amakhamera, ama-songer, amakhadi we-Pearl, i-pearl totholi. Umshini wokusika we-gasket ungafinyelela ukunemba okuphezulu nesivinini esikhulu, futhi ngokusheshe uqedele ukucutshungulwa okukhethekile kwezimpawu. Isisebenzi sokusebenza esiqediwe asinawo ama-sawtooth, akukho burrs, futhi bushelelezi ngokuvumelana okuhle.

Ividiyo

Izinzuzo

1. Akunasidingo sokusika idatha yokubumba

2. Isakhiwo esihlakaniphile, sigcina ama-20% +

I-3. I-Taiwan Guide Rail Riever, ukunemba ± 0.02mm

I-4

5. Amathuluzi aguqukayo, ukusika okulula kwamakhulu ezinto zokwakha

I-6. Ukusebenza okulula, abasebenzi abajwayelekile bangaqala umsebenzi ngamahora ama-2

7. I-Tungsten Steel Blade isekela i-Graphite Metal Gasket

8. I-Smooth cutter Edge, Azikho ama-Burrs

Imingcele yemishini

| Isifanekiso | I-Bo-1625 (Ngokuzithandela) |

| Uhlobo Olu-Optional | Itafula lokuphakela ngokuzenzakalela |

| Ubukhulu obuphezulu bokusika | I-2500mm × 1600mm (ngokwezifiso) |

| Usayizi ophelele | 3571mm × 2504mm × 1325mm |

| Inhloko yomshini womsebenzi omningi | Ithuluzi elimbaxambili lokulungisa amathuluzi, ithuluzi lokufaka okusheshayo kokuhlela, ukufakwa kwamathuluzi okusheshayo futhi okusheshayo kwamathuluzi okusika, ipulaki nokudlala, ukuhlanganisa ukusika, ukugaya, ukuvala kanye neminye imisebenzi (ngokuzithandela) |

| Ukucushwa kwamathuluzi | Ithuluzi lokusika eli-Electric Vibration, ithuluzi elindiza ummese, ithuluzi lokugaya, ithuluzi lokuvikela i-knife, ithuluzi lokuvala, njll. |

| Idivaysi yokuphepha | Ukuzwakala okungenampilo, impendulo ebucayi, iphephile futhi ithembekile |

| Isivinini esikhulu sokusika | I-1500mm / s (kuya ngezinto ezahlukahlukene zokusika) |

| Ubukhulu bokusika | I-60mm (ngokwezifiso ngokuya ngezinto ezihlukile zokusika) |

| Phinda ukunemba | ± 0.05mm |

| Izinto zokusika | I-Carbon Fibre / i-PrePreg, i-TPU / Base ifilimu, ibhodi le-carbon fiber curreg / indwangu eyomile, i-polyester redin film, ifilimu / indwangu yefilimu / i-file / indwangu ye-glass / xpe, graphite / Asbestos / irabha, njll. |

| Indlela yokulungisa izinto ezibonakalayo | Vacuum adsorption |

| Ukulungiswa kwe-servo | ± 0.01mm |

| Indlela yokuhambisa | I-Ethernet Port |

| Isistimu yokuhambisa | Uhlelo lweSerso oluthuthukisiwe, imihlahlandlela eqondile engenisiwe, amabhande avumelanayo, izikulufo eziholayo |

| X, y axis motor nomshayeli | X axis 400W, y Axis 400W / 400W |

| Z, w axis motor driver | Z axis 100w, w axis 100w |

| Amandla alinganiselwe | 11kw |

| Amandla kagesi | 380v ± 10 50hz / 60hz |

Izingxenye zomshini wokusika wezinto ezibonakalayo

Inhloko yomshini womsebenzi omningi

I-Dual Tool Fingting Holes, ithuluzi lokufaka okusheshayo kokuhlela, ukufakwa kwamathuluzi okusheshayo futhi okusheshayo kwamathuluzi okusika, ipulaki kanye nokudlala, ukuhlanganisa ukusika, ukugaya, ukuvala kanye neminye imisebenzi. Ukucushwa kwekhanda ngomshini okuhlukahlukene kungahlanganisa ngokukhululeka amakhanda womshini ejwayelekile ngokuya ngezidingo ezahlukahlukene zokucubungula, futhi angaphendula kalula ekukhiqizeni okuhlukahlukene kanye nezidingo zokucubungula. (Ngokuzithandela)

Izingxenye zomshini wokusika wezinto ezibonakalayo

Ukuvikelwa Kokuphepha Okuzungezile

Amadivayisi okuma eziphuthumayo kanye nezinzwa ze-infrared yezokuphepha zifakiwe kuwo wonke amakhona amane ukuqinisekisa ukuphepha okuphezulu komhlinzeki ngesikhathi sokuhamba ngejubane elikhulu lomshini.

Izingxenye zomshini wokusika wezinto ezibonakalayo

Ubuhlakani buletha ukusebenza okuphezulu

Abalawuli abasebenza ngokusebenza okuphezulu bahlome ngama-motor e-serso asebenza kakhulu, ubuchwepheshe obuhlakaniphile, obuhleliwe obuhleliwe kanye nemininingwane eqondile, yokushayela. Ngokusebenza okuhle kakhulu kokusika, izindleko ezisebenzayo zokusebenza kanye nokuhlanganiswa okulula kwezinqubo zokukhiqiza.

Isampula yomshini wokusika we-gasket

Ukuqhathaniswa kokusetshenziswa kwamandla

- Isivinini sokusika

- Ukusika ukunemba

- Izinga lokusetshenziswa kwezinto ezibonakalayo

- Ukusika izindleko

Izikhathi ezi-4-6 + ziqhathaniswa nokusika okwenziwa ngesandla, ukusebenza kahle komsebenzi kuyathuthukiswa

Ijubane lomshini we-Bolay

Ukusika okwenziwa ngesandla

Ukunemba okuphezulu, ukusebenza kahle okuphezulu, kanye nokusetshenziswa okungcono kwezinto

I-BOALY SCHINETING CUSTINCY ukunemba

Punch ukusika ukunemba

Uhlelo oluzenzakalelayo lokuthayela lusindisa ngaphezulu kwama-20% wezinto zokwakha uma kuqhathaniswa nokuhlelwa kwamagama

Ukusebenza Komshini Wokusika

Ukusebenza kahle kweManual

Ukusika ikhompyutha, asikho isidingo sokuvula isikhunta

Izindleko zokusika umshini we-Bolay

Izindleko zokusika ngesandla

Isingeniso Somkhiqizo

-

I-Electric Vibrating Knife

-

Ummese oyindilinga

-

Ummese we-pneumatic

-

Ithuluzi lokusika le-V-groove

I-Electric Vibrating Knife

Ihlotshiswe ngezinhlobonhlobo zama-blade, kufanelekile ukucubungula izinto ezahlukahlukene ezifana nephepha, indwangu, isikhumba nezinto eziguqukayo zenhlanganisela.

- Isivinini sokusika okusheshayo, imiphetho ebushelelezi namaphethelo wokusika

Ummese oyindilinga

- Isetshenziswa ikakhulukazi ezindwangu zokugqoka, amasudi, ama-knitwear, ngaphansi kwezingubo zangaphansi, amajazi oboya, njll.

- Isivinini sokusika okusheshayo, imiphetho ebushelelezi namaphethelo wokusika

Ummese we-pneumatic

- Kwezinto zokwenziwa ezithambile, zeluliwe, futhi zinokumelana okuphezulu, ungabhekisa kubo ngokusika kwengqimbanhlobo.

- I-amplitude ingafinyelela ku-8mm, futhi ibala lokusika liqhutshwa umthombo womoya ukuze udlidlize phezulu naphansi.

Ithuluzi lokusika le-V-groove

②threeree angles ehlukene yokusika (0 °, 30 °, 45 °, 60 °)

③Fast blade esikhundleni

Insiza yamahhala

-

Iwaranti yeminyaka emithathu

-

Ukufakwa kwamahhala

-

Ukuqeqeshwa kwamahhala

-

Ukulungiswa kwamahhala

Izinsizakalo zethu

-

01 /

Yiziphi izinto ezingasinquma?

Umshini wokusika we-gasket ngumshini wokusika ummese wokuvinjwa ongasetshenziswa kabanzi ekuvaleni ama-gaskets, irabha, i-asbestone, izinto ezingenazinhlanganisela ze-graphios, amakhokho, i-PTFE, iphepha lokuhlanganisa, imoto Ama-Mats, ama-Car Cariors, amabhokisi, amabhokisi anemibala, ama-PVC ama-PVC Crystal Pads, ama-Sockite Ring ring Umshini wokusika we-gasket ungafinyelela ukunemba okuphezulu, isivinini esikhulu, nokuqedwa okuningi okuzinzile kokucutshungulwa okukhethekile kwezimpawu zasolwandle. Isisebenzi sokusebenza esiqediwe asinawo ama-sawtooth, akukho burrs, futhi bushelelezi ngokuvumelana okuhle.

-

02 /

Yibuphi ubukhulu bokusika okukhulu?

Ubukhulu bokusika bomshini buxhomekeke kokuqukethwe kwangempela. Uma usika indwangu ehlukahlukene ehlukahlukene, kuphakanyiswa ukuthi ube ngaphakathi kwama-20 - 30mm. Ngicela ungithumele okuqukethwe kwakho nobukhulu ukuze ngikwazi ukuqhubeka nokuhlola futhi nginikeze izeluleko.

-

03 /

Yini ijubane lomshini lokusika?

Isivinini sokusika ngomshini singu-0 - 1500mm / s. Isivinini sokusika sincike kokuqukethwe kwakho kwangempela, ubukhulu, kanye nokusika iphethini, njll.

-

04 /

Iyiphi ingxenye yomshini esetshenziswayo kanye nesikhathi sokuphila?

Lokhu kuhlobene nesikhathi sakho somsebenzi kanye nesipiliyoni sokusebenza.

-

05 /

Ingabe umshini wokusika we-gasket ungasika izinto ezahlukene ngasikhathi sinye?

Ngokuvamile, umshini wokusika we-gasket kungenzeka ungakwazi ukusika izinto ezahlukahlukene ngasikhathi sinye ngendlela efanele.

Indwangu ngayinye inezakhiwo zayo ezihlukile njengokulukhuni, ubukhulu, kanye nokuthungwa. Amapharamitha wokusika afana nesivinini sokusika, ingcindezi, nohlobo lwe-blade ajwayele ukulungiswa ngezinto ezithile. Izama ukusika izinto ezahlukahlukene ngasikhathi sinye kungaholela kwikhwalithi yokusika engahambisani.

Isibonelo, izinto ezithambile ezifana nenjoloba zingadinga ingcindezi encane kanye nemvamisa ehlukile ye-oscillation imvamisa ngokuqhathaniswa nezinto ezinzima njenge-graphite. Uma usike ndawonye, enye into ingagawulwa kahle kanti enye ingahle ibe nezinkinga ezinjengamaphethelo angenamikhawulo, ukusikeka okungaphelele, noma ngisho nomonakalo emshinini.

Kodwa-ke, kwezinye izimo, uma izinto zokwakha zinezinto ezifanayo futhi umshini ulungiswa kahle futhi uhlolwe, kungenzeka ukuthi usike inhlanganisela ethile yezinto zokwakha ezinemiphumela emihle. Kepha ngokusika okuseqophelweni eliphezulu nokungaguquguquki, kunconywa ukusika uhlobo oluthile lwezinto ezibonakalayo ngasikhathi.

-

06 /

Yiziphi izinto eziphambili ezithinta ikhwalithi yokusika yomshini wokusika we-gasket?

Ikhwalithi yokusika yomshini wokusika we-gasket ithonywa yizinto ezimbalwa eziphambili:

** 1. Izakhiwo Ezibonakalayo **

- ** Ubulukhuni **: Izinto zokwakha ezinamazinga ahlukene bunzima zidinga amabutho ahlukile wokusika. Izinto ezinzima zingadala ukugqoka okwengeziwe kwithuluzi lokusika futhi lingadinga isenzo esinamandla sokusika, esingathinta ubushelelezi nokunemba kokusikiwe.

- ** Ubukhulu **: Izinsiza ezinkulu zingaba nzima ukusika ngokulinganayo. Umshini udinga ukuba namandla anele kanye nendlela efanele yokusika yokuphatha izinto ezibukhali ngaphandle kokubangela ukusikeka okungalingani noma ukusikeka okungaphelele.

-** 2. Isimo samathuluzi wokusika **

- ** Ubukhali be-Blade ** Ukulungiswa njalo kanye nokufakwa esikhundleni kwecala kubalulekile ukuze kuqinisekiswe ikhwalithi enhle yokusika.

- ** Uhlobo lweBlade **: Izinto ezahlukahlukene zingadinga izinhlobo ezithile zama-blade. Isibonelo, ummese ovuthayo kungenzeka ulungele izinto ezithile ezithambile, ngenkathi i-rotary blade ingasebenza kangcono ngezinto eziqinile noma ezinzima.

- ** I-Blade Wear **: Ngokuhamba kwesikhathi, ibala lizogqoka phansi ngenxa yokusetshenziswa okuqhubekayo. Ukugqokwa kwe-blade kungathinta ukunemba okusika kanye nekhwalithi, ngakho-ke ukuqapha ukugqoka kwe-blade nokuyifaka esikhundleni lapho kunesidingo kubalulekile.** 3. Amapharamitha womshini **

- ** Ukusika isivinini **: Ijubane lapho ukusikeka komshini kungaba nomthelela omkhulu kwikhwalithi yokusikwa. Ngokushesha kakhulu isivinini sokusika kungahle kuholele ekusikeni okungaphelele noma imiphetho emibi, ngenkathi kuhamba kancane kakhulu ngejubane kunganciphisa umkhiqizo. Ukuthola ijubane elifanelekile lokusika kokuqukethwe okuthile kubalulekile.

- ** Ingcindezi Ingcindezi enganele kungenzeka inganqunywa ngendlela efanele, ngenkathi ingcindezi eyeqile ingalimaza izinto ezibonakalayo noma ngomshini.

- ** I-Vibration Frequency **: Endabeni yomshini wokusika ummese ovuthayo, imvamisa yokudlidliza kungathinta ikhwalithi yokusika. Izinto ezihlukile zingadinga imvamisa yokudlidliza ehlukile ukufeza imiphumela emihle.** 4. Ikhono le-opharetha kanye nesipiliyoni **

- ** Ukunemba kokuhlela **: I-opharetha idinga ukufaka amaphethini aphezulu wokusika kanye nobukhulu kwisoftware yomshini. Amaphutha ezinhlelo angaholela ekunciphisweni okungalungile kanye nokuchitha izinto zokwakha.

- ** Ukuphathwa Kwezinto Ezibonakalayo **: Ukuphathwa okufanele kwezinto zokwakha ngesikhathi sokulayisha nokulayisha kungavimbela ukulimala kokuqukethwe futhi kuqinisekiswe ukuma okunembile kokusika. Opharetha onolwazi bazokwazi ukuphatha izinto ezahlukahlukene ukunciphisa ubungozi bamaphutha.

- ** Ukulungiswa Kokuxazulula Izinkinga** 5. Izici zezemvelo **

- ** Izinga lokushisa **: Amazinga okushisa aphezulu angathinta ukusebenza komshini nezinto zokwakha. Ezinye izinto zokwenziwa zingahle zibe brittle noma zithambile emazingeni okushisa ahlukene, angathinta ikhwalithi yokusika.

- ** Umswakama **: Umswakama ophezulu ungadala ezinye izinto ukuthi zithole umswakama, ezingathinta izakhiwo zazo zokusika. Kungabuye kuholele ekugqwayineni noma ukugqwala ezingxenyeni zensimbi zomshini.